In today’s fast-paced industrial landscape, effective maintenance processes are no longer a luxury but a necessity for organizations aiming to stay competitive. The journey toward optimized maintenance has seen significant transformation with the advent of digitalization, the Industrial Internet of Things (IIoT), and Artificial Intelligence (AI). This blog explores how these technologies are revolutionizing maintenance practices, step by step.

The Four Levels of Maintenance Evolution

- Digitalization (Reactive Maintenance): The Foundation

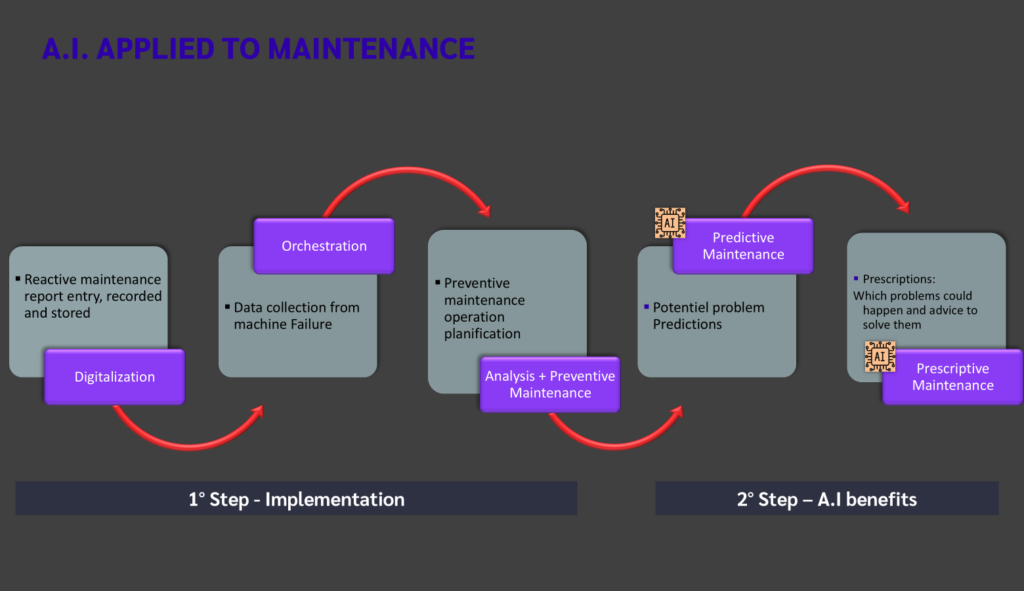

The first step in the evolution of maintenance involves digitizing maintenance records. Traditionally, maintenance data was logged manually, making it prone to errors and difficult to analyze. Digitalization resolves these issues by storing accurate and reliable data electronically. Though reactive in nature—addressing equipment failures after they occur—this step lays the groundwork for more advanced maintenance strategies by ensuring that critical data is available for analysis. - Orchestration (Preventive Maintenance): Planning Ahead

Building on the foundation of digitalized data, the second level focuses on preventive maintenance. By analyzing historical data, organizations can anticipate potential failures and plan maintenance schedules proactively. This approach minimizes unexpected breakdowns, enhances equipment lifespan, and improves operational efficiency. - Predictive Maintenance: The AI Revolution

Predictive maintenance introduces AI into the equation. Using advanced algorithms, AI analyzes historical and real-time data to predict when equipment is likely to fail. By identifying trends and anomalies, this level empowers companies to address issues before they escalate, significantly reducing unplanned downtime and maintenance costs. - Prescriptive Maintenance: Turning Insights into Action

The pinnacle of maintenance evolution is prescriptive maintenance, where AI not only predicts potential failures but also provides actionable recommendations. By combining predictive insights with prescriptive advice, organizations can make informed decisions about the best course of action. This ensures not only the prevention of failures but also the optimization of resources and processes.

Why Digitalization, IIoT, and AI Matter

The integration of digitalization, IIoT, and AI into maintenance processes brings unparalleled benefits:

- Reliable Data Storage: Digitalization ensures that maintenance data is accurate, accessible, and ready for analysis.

- Real-Time Monitoring: IIoT enables continuous monitoring of equipment performance, facilitating rapid response to emerging issues.

- Advanced Analytics: AI leverages historical and real-time data to predict failures and recommend solutions, optimizing maintenance operations.

The image outlines the evolution of maintenance processes and how incorporating digitalization, IIoT (Industrial Internet of Things), and AI is transforming maintenance practices. Below is an explanation:

Benefits for the Pharmaceutical Industry

For industries like pharmaceuticals, where equipment reliability and compliance with stringent regulations are paramount, adopting digitized maintenance processes is transformative. Key benefits include:

- Minimized Downtime: Predictive and prescriptive maintenance reduce unexpected equipment failures, ensuring uninterrupted production.

- Regulatory Compliance: Detailed and reliable maintenance records help meet stringent industry standards.

- Enhanced Quality Assurance: Consistent equipment performance guarantees product quality and reliability.

- Cost Savings: Optimized maintenance schedules and reduced downtime lead to significant cost reductions.

The Road Ahead

The digitization of maintenance processes, coupled with IIoT and AI, is not just a trend but a necessity for industries looking to thrive in a competitive environment. By evolving through the levels of reactive, preventive, predictive, and prescriptive maintenance, organizations can achieve unprecedented efficiency, reliability, and cost-effectiveness.

Whether you’re just beginning your digital transformation journey or advancing to the next level, the benefits of adopting these technologies are clear. Embrace the future of maintenance today and stay ahead in the ever-evolving industrial landscape.