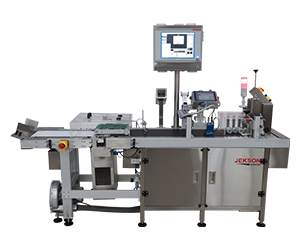

SF100R - the ultimate offline serialization & verification of flat cartons with Stacking & Restacking option.

Compact, cGMP Compliant Design.

Compact, cGMP Compliant Design. Flawless data transfer & handshaking through seamless integration to L3/L4 software.

Flawless data transfer & handshaking through seamless integration to L3/L4 software. Output speed up to 300 CPM.

Output speed up to 300 CPM. Option of Stacking and Restacking, allowing product handling during print & inspection phases.

Option of Stacking and Restacking, allowing product handling during print & inspection phases. Compatible with verification of leaflet & booklet.

Compatible with verification of leaflet & booklet. Come with options of flapper, air, or pusher-based rejection system with verification.

Come with options of flapper, air, or pusher-based rejection system with verification. Equipped with a vacuum-based conveyor system, the machine ensures 100% product stability.

Equipped with a vacuum-based conveyor system, the machine ensures 100% product stability. Incorporates a secured rejection bin with Track & Trace software (REETRAK).

Incorporates a secured rejection bin with Track & Trace software (REETRAK). The machine is designed to withstand vibrations when the product is in motion.

The machine is designed to withstand vibrations when the product is in motion. Equipped with a user-friendly touchscreen interface.

Equipped with a user-friendly touchscreen interface. Supports a variety of thermal inkjet printers along with laser printers with an online print system.

Supports a variety of thermal inkjet printers along with laser printers with an online print system. Designed for easy and tool-less mechanical setting.

Designed for easy and tool-less mechanical setting. Suitable for both offline & online printing & inspection of 2D and OCR codes.

Suitable for both offline & online printing & inspection of 2D and OCR codes.Unlock a new era of precision and efficiency with the SF100R, a cutting-edge product that redefines the standards of offline flat carton serializations and verification.

The machine is engineered to verify leaflets and booklets. It seamlessly integrates serialization and verification, ensuring unparalleled accuracy and security in your processes.

Printing & Inspection of: