The data needs to be sent to cloud to be analyzed,but it needs a way to get there.

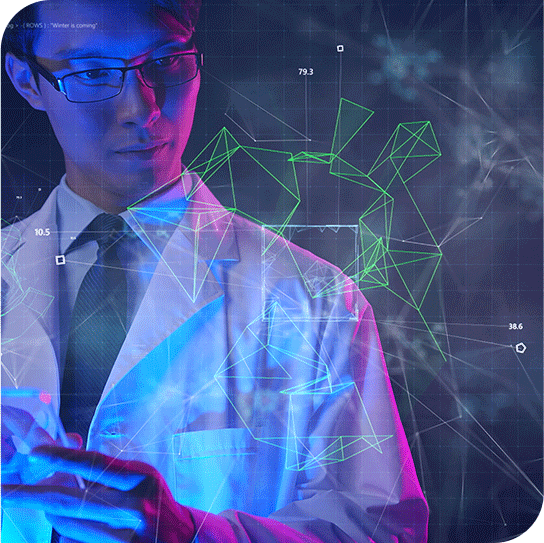

REESMART is an advanced Smart Factory solution that leverages the power of IoT to transform your manufacturing efficiency. This smart system seamlessly integrates into your existing factory line with minimal modifications, enabling a smooth transition to smarter production processes. REESMART enhances your operations by utilizing real-time data on critical performance indicators like Machine Availability, Operation Performance, and Production Quality.

With Jekson’s IoT box, the system securely gathers data in the cloud, where cutting-edge Artificial Intelligence tools analyze it. The result is a comprehensive REESMART report, visually intuitive and packed with valuable insights such as key downtimes, trend evaluations, and predictive analysis. These insights empower smarter, data-driven decisions, offering a strategic advantage. Combining real-time intelligence with advanced analytics, REESMART brings a new level of efficiency and optimization to your factory operations—ushering in the era of Smart Factory solutions.

The data needs to be sent to cloud to be analyzed,but it needs a way to get there.

ReeSmart collects the data from the Sensor/Devices environment or PLCs.

To ensure data security, protocols such as HTTPS, OPC UA, MQTT, etc., are used.

The data is transmitted to the cloud via Gateways using both cellular as well as satellite communication.

Once data gets into the ReeSmart cloud, it will be processed to calculate efficiencies.

Processed information is made useful to the end user by providing alerts, and emails.

Use Data Analytics to make use of historical data for actionable insights.

You can make intelligent business decisions based on insights and predictions from generated data.

The data needs to be sent to cloud to be analyzed,but it needs a way to get there.

ReeSmart collects the data from the Sensor/Devices environment or PLCs.

To ensure data security, protocols such as HTTPS, OPC UA, MQTT, etc., are used.

The data is transmitted to the cloud via Gateways using both cellular as well as satellite communication.

Once data gets into the ReeSmart cloud, it will be processed to calculate efficiencies.

Processed information is made useful to the end user by providing alerts, and emails.

Use Data Analytics to make use of historical data for actionable insights.

You can make intelligent business decisions based on insights and predictions from generated data.

The software system is fully managed by Jekson and hosted on a highly secured Azure cloud platform

With Jekson’s state-of-the-art system the data can be captured from data points on equipment with no to less modifications

Jekson’s REESMART system’s key feature lies in real-time performance & productivity monitoring with the capability of monitoring stoppages

This OEE system offers extensive and insightful reports in real-time on equipment productivity and stoppages.

The OEE software system provides actionable data to the operator in real-time on parameters like delays, total run time against remaining time, total quantity of good products against total quantity of good products needed, etc.

A stoppage summary is reported including a master configuration for in-depth analysis and action points on continual improvements in the factory performance

In-depth details on running jobs with REESMART trend analysis, reject count summary, accept or reject trends, shift-wise REESMART, & equipment-wise REESMART