11th – 13th September 2023

Las Vegas, NV, USA

Where Innovation Meets Precision

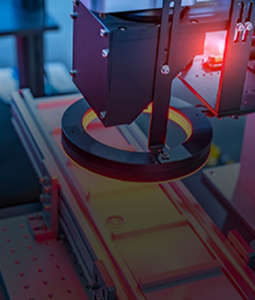

At Jekson, we pride ourselves on our unwavering dedication to research and our relentless pursuit of new and original solutions in the Track & Trace and Vision Inspection systems. It is this commitment to innovation that sets us apart from others in the industry. By constantly seeking out innovative ways to anticipate trends and staying ahead of the curve, we have positioned ourselves as pioneers in our field. Our fearless attitude towards innovation empowers our teams to explore new paths and embrace novel approaches, ensuring that we continuously deliver cutting-edge automated inspection systems to our clients.

SLA provides you peace of mind with our service engineers spanning all over the world and just a call away. We are a detriment to providing online and offline service and assistance to maintain overall efficiency in our partner’s manufacturing plant.

Years of Experience

Installations Worldwide

Clients Worldwide

Product Lines

Countries served

Global Offices

We believe innovation is deeply rooted in - our legacy, our long-lasting partnerships over the years, and our human capital. Growth is the perfect matrix to measure industry-relevant innovations, and our growth story is a standing example of this.

We are the number 1 partner of choice with our customers and OEM manufacturers for more than 22 years with about 1000+ successful projects all over the world

We are a global family with manufacturing set-ups in India, US, and Europe. With our development centers all around the globe we bring you the best of all worlds.

With a vast range of solutions and our expertise in Vision Inspection and Track & Trace, we support partners across all industries

We've crafted our inspection software through extensive experience and global partner brainstorming. Our tech features top-tier UI & UX, plus performance for current and future needs.

Our systems are futuristic and autonomous, rendering them highly reliable for various operations while also ensuring compliance. Our vision inspection solutions are equipped with Machine Learning, ensuring their efficiency on a daily basis.

Our automated vision inspection systems are retrofittable and upgradeable, making them flexible and adaptable.

Reesource Architecture Overview

Warehouse

Compliance

Customer

Logistics

Industry

Reesource Architecture Overview

Traceability solutions for warehousing and product storage

Traceable solutions to meet different compliance requirements

Traceability solutions to ensure customers get genuine products only

Traceability solutions for logistics and product movement

Traceability solutions for the industry right from sourcing to packing

Life at Jekson Vision is not just a job, it's a dynamic journey filled with boundless possibilities and exhilarating challenges. We are committed to onboarding the best minds in the industry and providing them with a platform to flourish. Our rigorous talent acquisition process ensures that we assemble a team of passionate professionals who embody our values of innovation, collaboration and excellence.